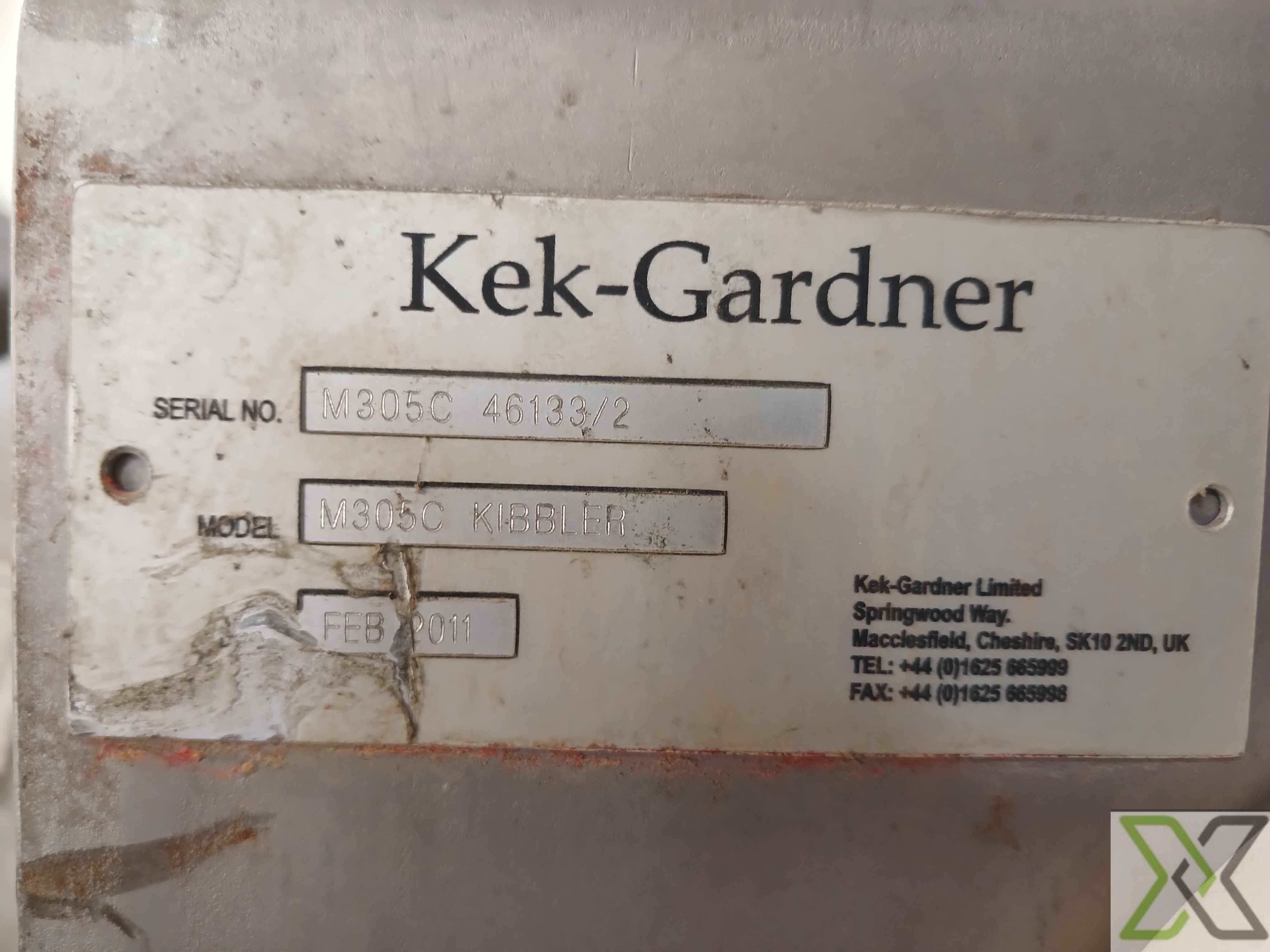

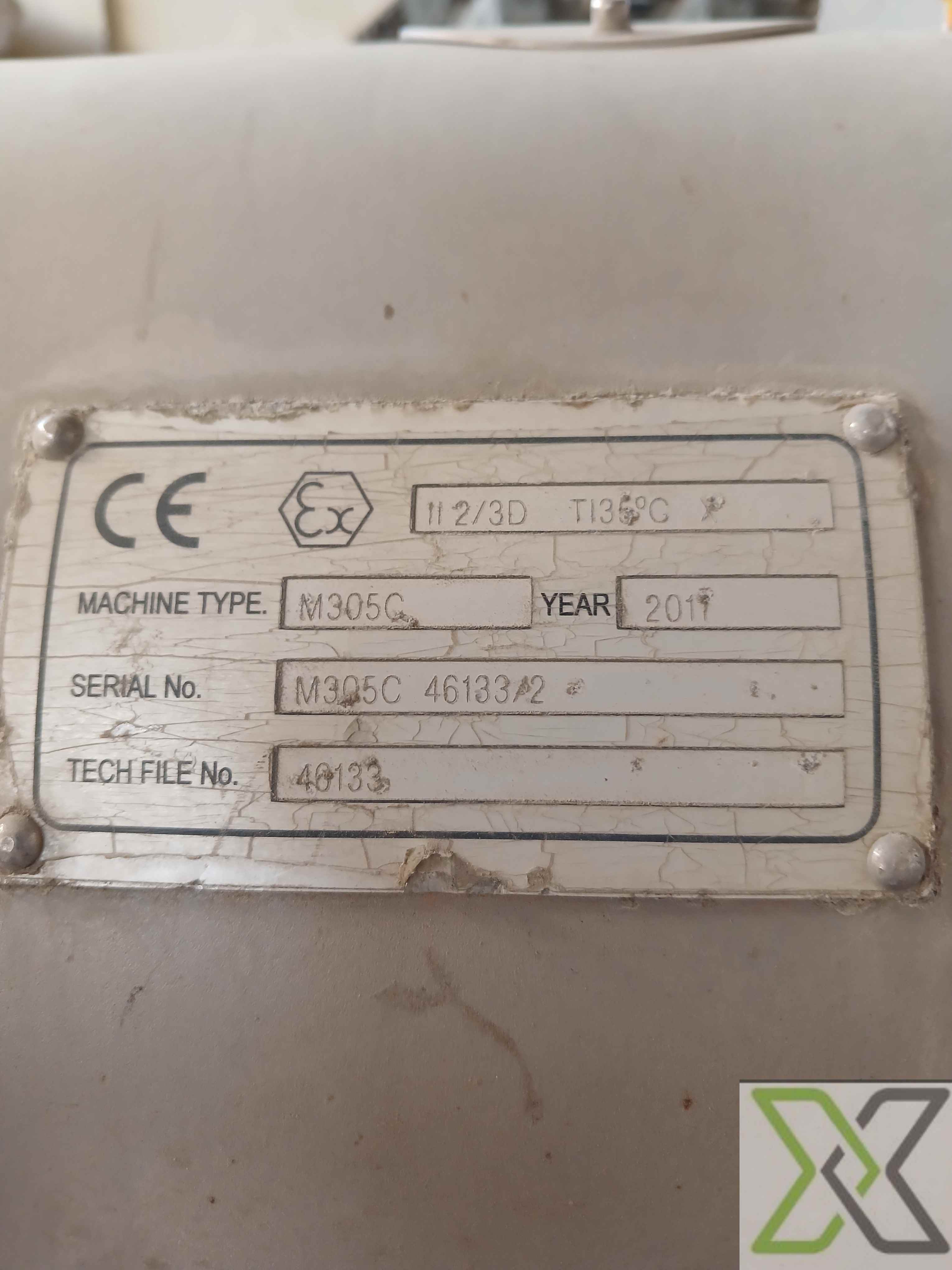

| Model Number

|

M305C Kibbler

|

|---|---|

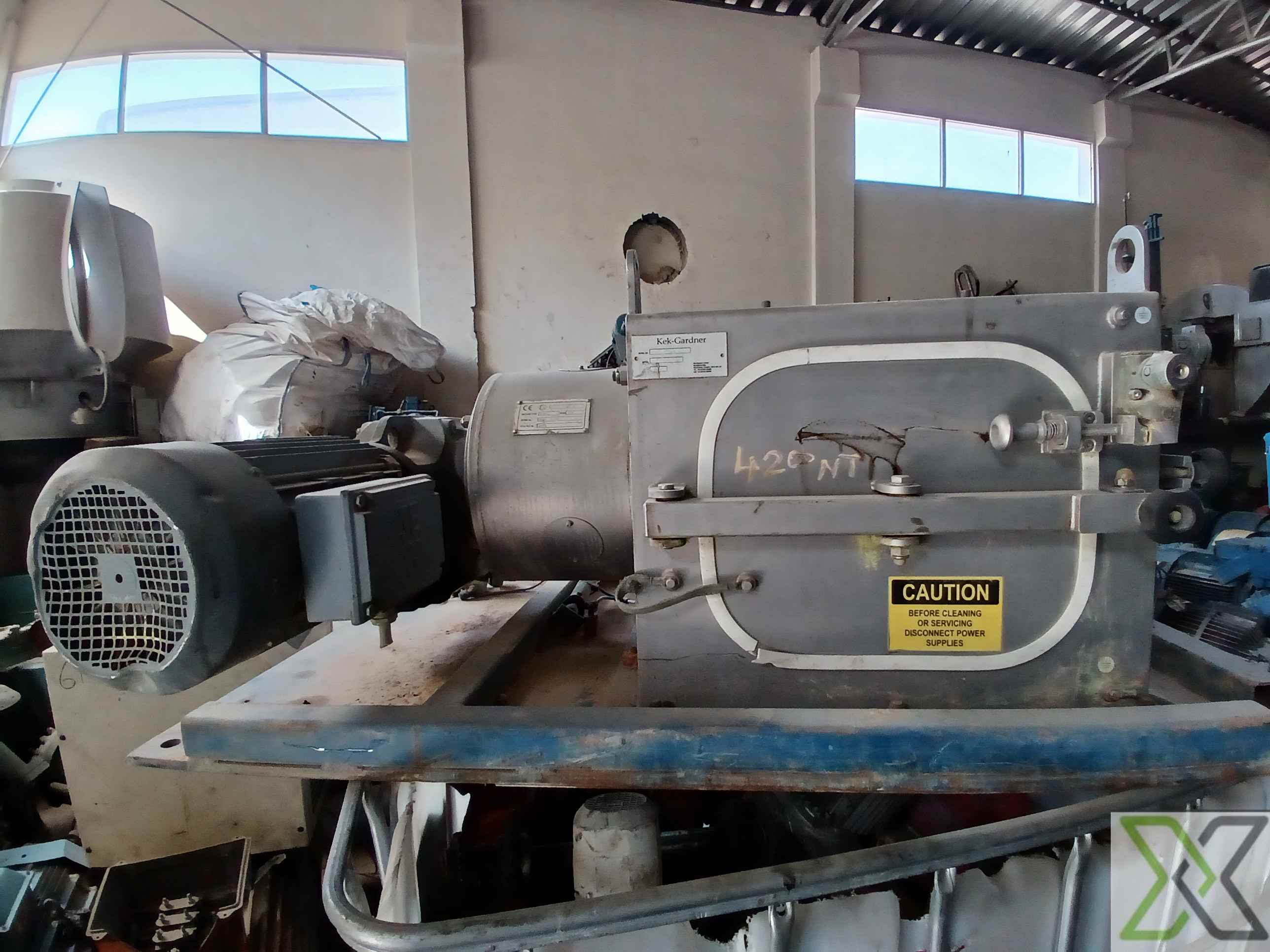

| Height

|

1,500 mm to 2,000 mm

|

| Width

|

800 mm to 1,200 mm

|

| Length

|

1,200 mm to 1,800 mm

|

×

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Or

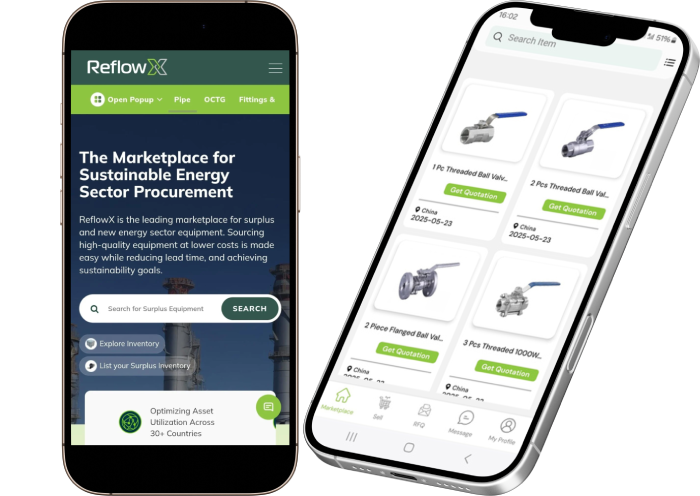

Login into your Reflowx account

Sign in with Google

Sign in with Google

Or

When creating a new account you agree to Reflowx Terms and conditions and Privacy Policy

New to Reflowx? Create an account

(4)_1729176674.webp)